TLC Group as a leader of steel structures sector is a specialist in production of industrial, technical and spiral stairs and is active in whole Europe. Thanks to well qualified and experienced team, modern production plant and innovative, high quality products TLC created strong and stable position on the market.

Our constructions are dedicated to many different market sectors such as building, industrial, energy, mining or steel.

TLC manufactures products especially fitted to global client’s needs and conditions. Thanks to knowledge, experience and workers involvement we produce a wide range of industrial sector goods with the highest safety standards.

By employing 250 people we are able to produce about 5 thousand tons of constructions yearly, and by using modern production technologies we guarantee high quality of offered goods and services.

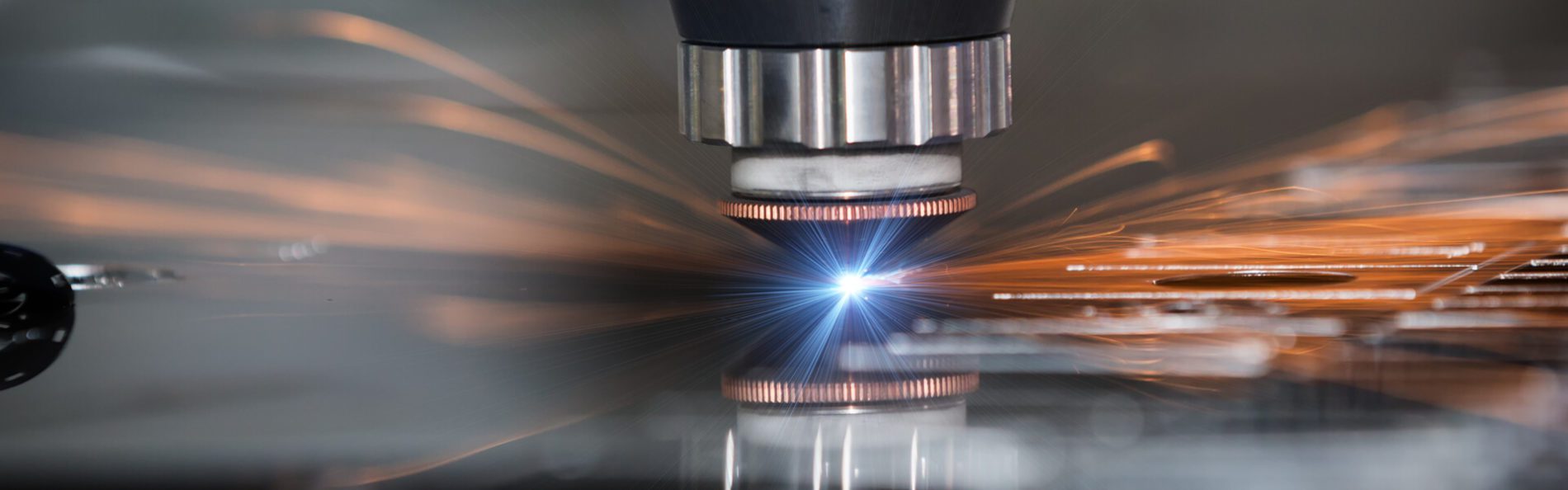

TLC Group has got a modern production plant placed in Poland. Laser and plasma cutting machines with the highest technological standards make all cut elements 100% repeatable. Specialised CNC bending machines create the goods with proper precision and matching. Welding machines provide high process automation and keep the highest quality standards.

The combination of modern, specialist production plant with powder paint shop and well qualified personnel allows TLC for complex and professional realisation of multimillion investments in Poland and the rest of world.

BLASTING CHAMBER

We offer a number of surface preparation for coating services. One of the most effective of the methods we use for mechanical cleaning is abrasive blasting, which is done in our blasting chamber.

POWDER PAINT SHOP

We have the largest and most modern powder paint shop in Gorlice, Poland. This allows us to deliver perfectly-finished products in terms of both aesthetics and strength. We constructed the factory with funds from the European Union.

Our dual, modern paint shop station has an automatic pass and large size stoves with operating dimensions of 14m length, 2.4m height and 1.5m width.

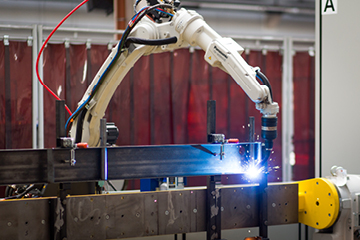

WELDING ROBOT

MAC WELDING OF CONSTRUCTION AND STAINLESS STEEL

- 2 short working fields length 4 000 mm; width: 1 500 mm

- 1 long working area: length 10 000 mm; width:1 500 mm

- Max. load (short field): 500 kg

- Max. load (long field): 1 000 kg

LASER CUTTING

PROFILES, OPEN SECTIONS, TUBES

- The materials of construction steel and stainless steel with a circular (Ø15 – 24O mm), square

(Ø15 – 200 mm), rectangular, oval flat and special excircled cross-section with a diameter of 240 mm - Min. load length: 2 500 mm, max. 12 500 mm, max. load weight: 40 kg/m

- Flat profiles: 40×5 – 200×12 mm; L, C, U profiles: 30×20 – 200×200 mm

- Max. thickness of the material to be cut: 15 mm – black steel, 10 mm – stainless steel

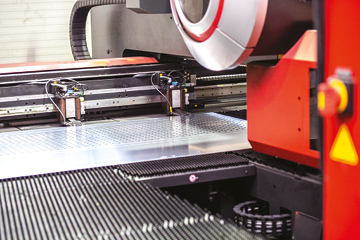

CNC PUNCHING MACHINE

METAL SHEET, PERFORMATING AND RIBBING

- Max sheet size 1 500 x 3 000 mm

- Plain steel and aluminum with a punched sheet thickenss of 0.5 – 3 mm

- One – sided steel processing margin: 50 mm

- Material: S235, S355, DC01, corten, aluminum, Z275 galvanized sheed

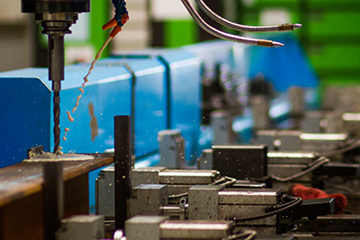

CNC DRILL

DRILLING, MILLING, THREADING IN AUTOMATIC CYCLE

- Working range: length 8 000 mm (optionally: up to 10 000 mm); width: 580 mm

- Max. diameter of the drilled hole: 32 mm

CNC PLASMA CUTTER

PLASMA AND OXYGEN CUTTING

- Working field: length 6 000 mm; width 2 000 mm

- Cutting sheets fron construction steel using plasma (steel thickness up to 25mm) or oxygen (up to 40 mm) method.